We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

AL/AXL

High duty rotary valve

AL/AXL

High duty rotary valve

AL/AXL DAIRY

High duty rotary valve

AL/AXL DAIRY

High duty rotary valve

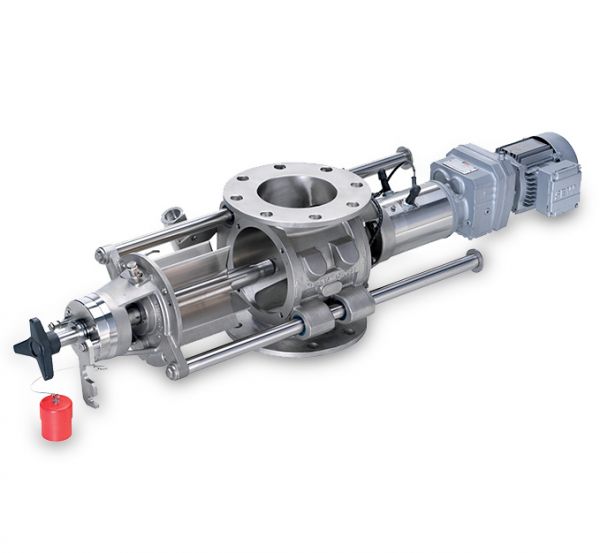

AL/AXL DAIRY MZC with slide rails

High duty rotary valve

AL/AXL DAIRY MZC with slide rails

High duty rotary valve

AML

High duty rotary valve

AML

High duty rotary valve

USAL

High duty rotary valve

USAL

High duty rotary valve

Blowing seal - BL/BXL/BXXL

High duty rotary valve

Blowing seal - BL/BXL/BXXL

High duty rotary valve

Blowing seal- BL/BXL/BXXL Dairy

High duty rotary valve

Blowing seal- BL/BXL/BXXL Dairy

High duty rotary valve

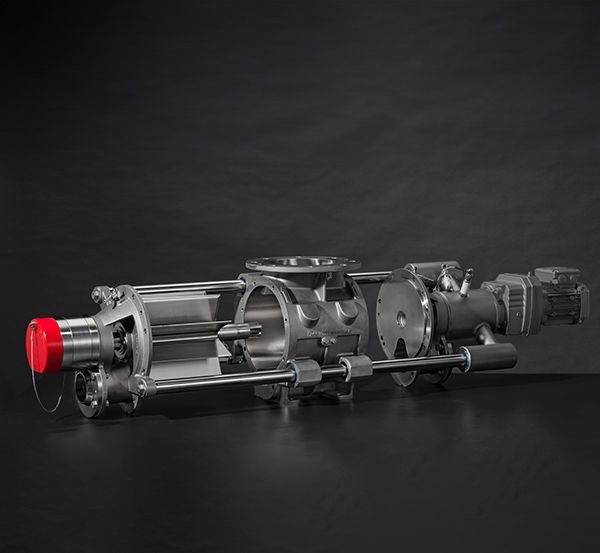

Blowing seal BL/BXL/BXXL Dairy MZC with slide rails

High duty rotary valve

Blowing seal BL/BXL/BXXL Dairy MZC with slide rails

High duty rotary valve

MLD

Medium duty rotary valve

MLD

Medium duty rotary valve

MALD

Medium duty rotary valve

MALD

Medium duty rotary valve

SAL

Sanitary rotary valve

SAL

Sanitary rotary valve

GL – GRANULAR ROTARY VALVE

GL – GRANULAR ROTARY VALVE

DL

Dust filter rotary valve

DL

Dust filter rotary valve

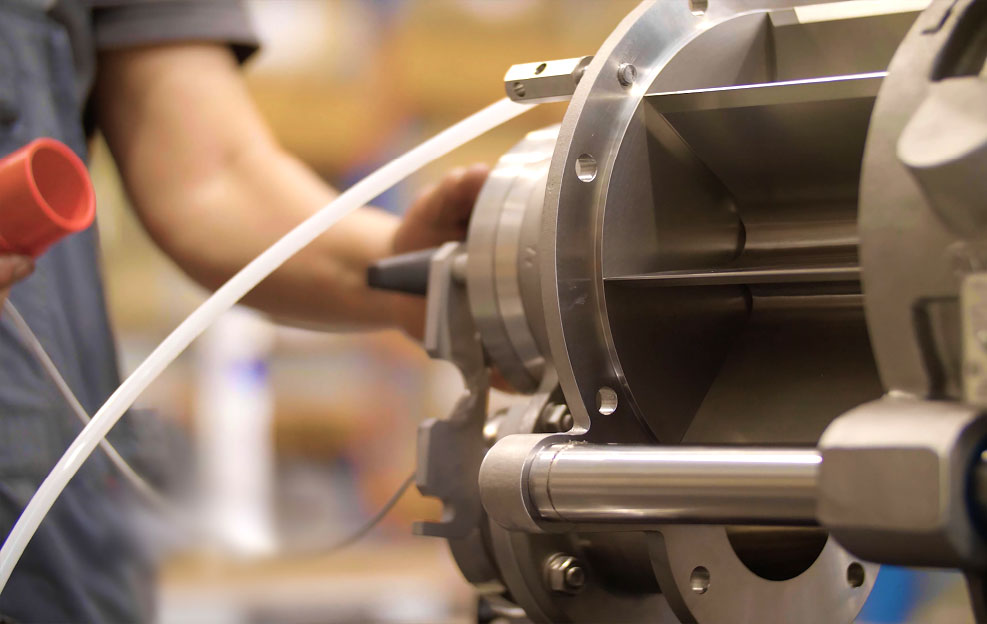

MZC-II

MAXIMUM CLEANABILITY, HYGIENE AND SAFETY

MZC-II

MAXIMUM CLEANABILITY, HYGIENE AND SAFETY

MZC-I

MZC-I

NR347

NR347

Thank you!

We have received your message and we are looking forward to be in touch with you.

One moment..

*Based on litre / FT3 per revolution at 100% filling.

*Based on litre / FT3 per revolution at 100% filling.

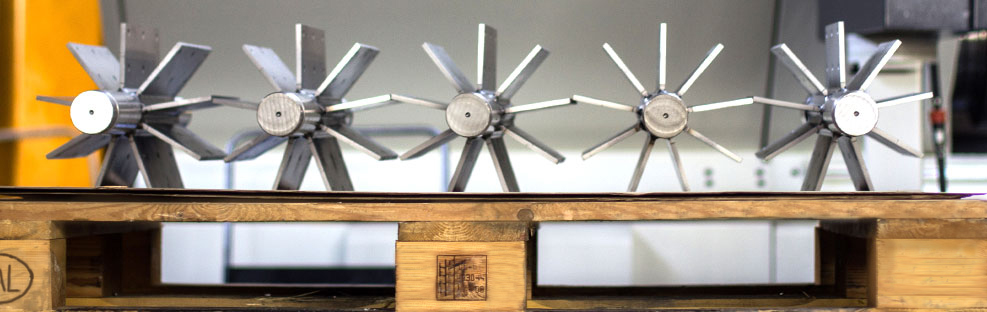

We specialize in providing high-end, custom-made solutions for our customer's unique needs

We specialize in providing high-end, custom-made solutions for our customer's unique needs. Our products have a proven track record of handling various dry powders and granular materials, including sugar, cocoa, starch, flour, chemical ingredients, lime powder, china clay, fly ash, and wood chips. We offer several standard rotary valves that can be upgraded to suit the specific product being handled and specialized housing options for abrasive products like fly ash. Our unique rotor can also be fitted in the valve for processing sticky products or starch. Please let us know how we can assist you further.