We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

Share a few details about your materials and application, and our team will match you with the ideal diverter valve solution — reliable, efficient, and designed to keep your production running smoothly.

Thank you!

We have received your message and we are looking forward to be in touch with you.

Something went wrong

One moment..

Whether you're handling dealing with particularly challenging flow properties, or working under extreme conditions your material challenge has likely crossed our desk before.

With so many variables affecting performance, choosing the right diverter valve configuration can be complex. Let us simplify it for you. Share your material details and specific needs, we'll recommend the precise diverter valve solution that ensures reliable operation.

We've spent decades learning how thousands of different materials behave in real applications. Our in-house R&D team doesn't just design diverter valves they solve material handling puzzles that keep production lines running smoothly. From our own factory, every diverter valve undergoes 100% end-of-line testing because we know that reliability isn't negotiable when your production depends on it.

At DMN-WESTINGHOUSE we are dedicated to keeping your business going. Today and in the future. Our rotary valves and diverter valves meet and exceed the highest standards in the industry.

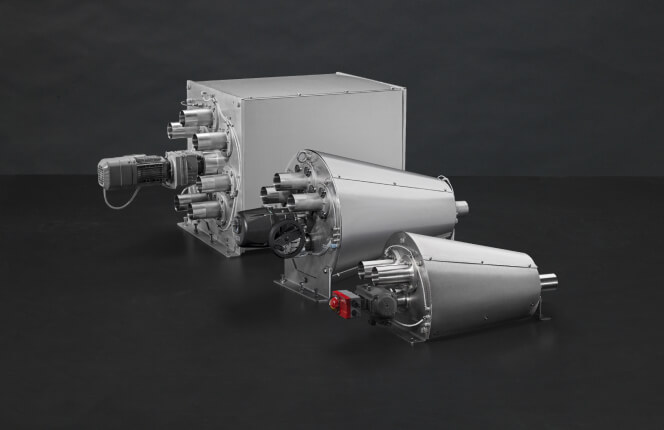

DMN-WESTINGHOUSE has developed diverter valves for rapid pipe changeover between powders and pellets in pneumatic conveying systems. Diverter valves are categorised into various types based on operating principles and design, such as plug, tube, flap, or ball types, each suited for pipe changeover tasks. For a complete overview of all our diverter valves you can also consult our diverter valve brochure.